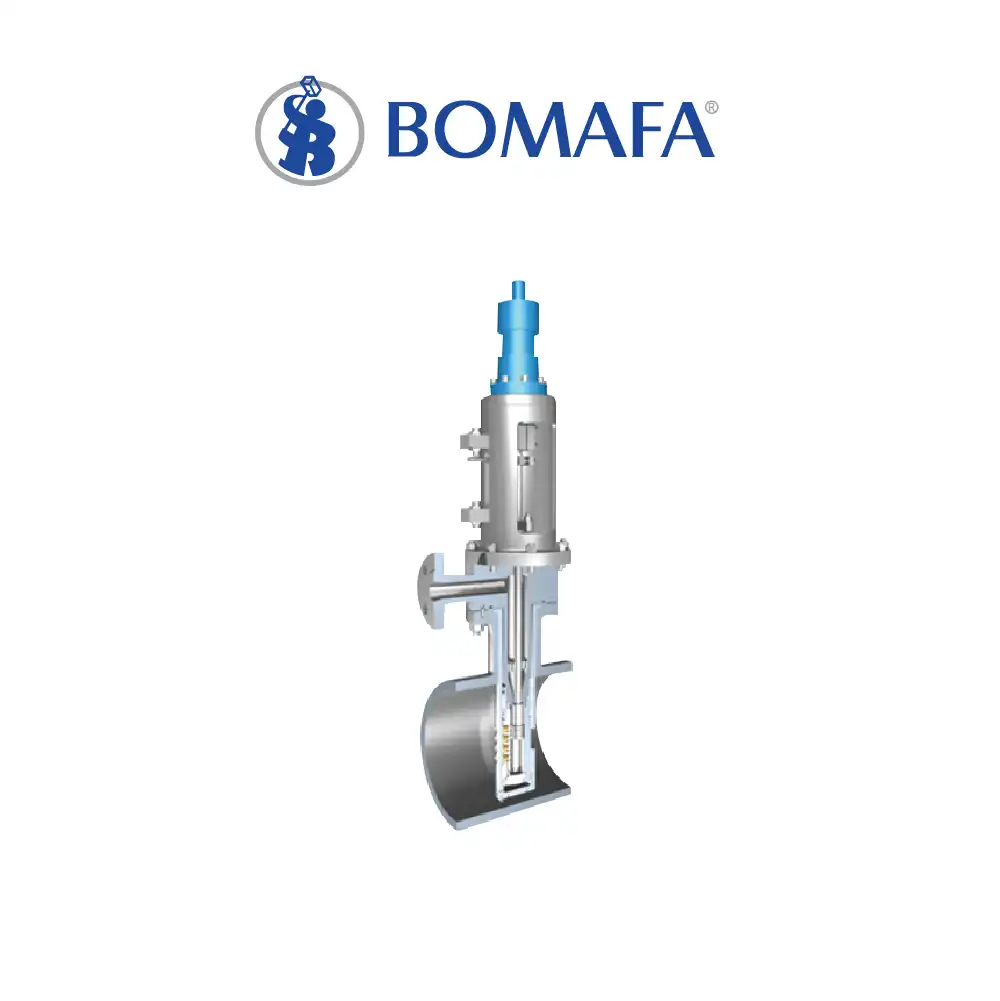

Design Features

- Exactly control of each nozzle possible

- Wear-resistant sealing of all control elements

- Contains integrated control valve for cooling water injection

Data: Variable Nozzle Desuperheater

DN of steam line: from DN 200

DN of water line: from DN 15

Connection of Desuperheater to steam line: Probe type, flanged

Connection of Desuperheater to steam line: Flange

Type of nozzles: Hollow cone nozzles

No. of nozzles: 1 – 6

Min. steam velocity: 8 m/s

Turndown ratio: 1 : 12